The worsening crisis in the semiconductor industry has now caused the 2021 worldwide automotive production forecast to be downgraded sharply to 73 million vehicles (versus 79 million in July 2021). For the second semester alone, IHS lowered its forecast by 15%.

The impact of semiconductor shortages on the automotive sector is increasing, impeding production by almost 4 million vehicles in the third quarter alone compared to July’s initial forecast of around 500,000. This new decline is equal to the entire output lost in the first half of 2021.

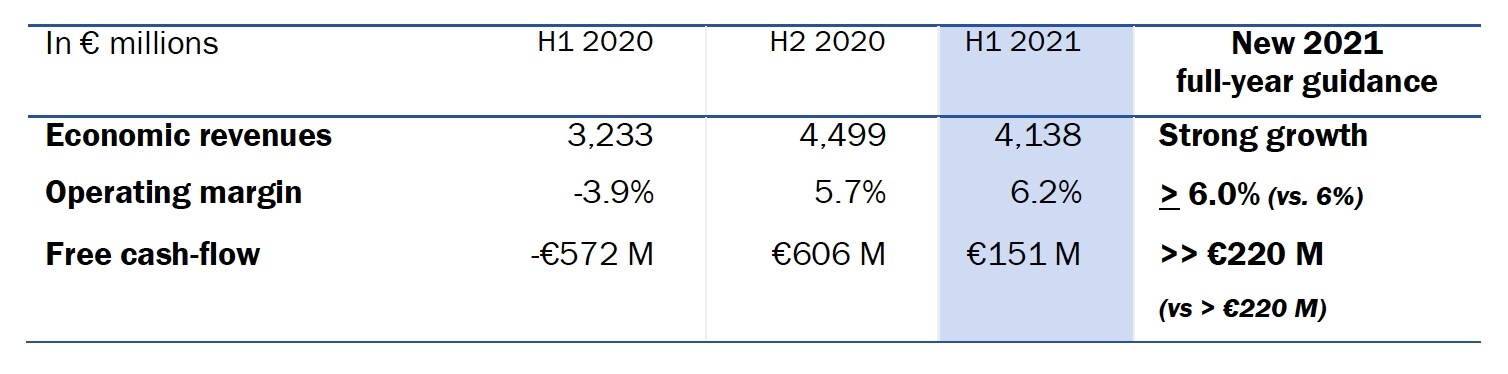

Updated financial guidance for 2021

Whilst the market had expected a return to normal conditions in the third quarter of 2021, in line with our clients’ order levels, the sudden worsening of production stoppages in plants around the world in recent weeks, together with IHS Markit’s revised figures, has prompted the Group to update its 2021 guidance based on worldwide automotive production of 71-73 million vehicles versus 77 million previously.

As a result, the Group’s new full-year 2021 guidance is as follows:

– Growth in revenue (versus the strong rebound previously expected)

– Operating margin of 4-5% (versus at least 6%)

– Free cash flow of at least €220 million (versus significantly more than €220 million)

Addressing increase in volatility through greater cost-reduction efforts and focus on flexibility

The significant decline in vehicle production also brings scheduling difficulties, volatile production levels and minimal visibility for Plastic Omnium.

Efforts to reduce costs and improve flexibility, which proved effective in the first half of 2021 when the operating margin increased to 6.2%, are being ramped up. Free cash flow remains a priority for the Group, with strict control over capital expenditure and working capital requirements. In the short term, these efforts will partially offset the impact of volatility on production volumes. However, the Group will also actively monitor and maintain its ability to respond rapidly to carmaker demand when shortages start to ease and demand and the need to rebuild inventories lead to a sharp recovery in production volumes.

Strategic roadmap confirmed

Due to its teams’ commitment, robust business model, solid order book and leading position in all its market segments, Plastic Omnium is optimally positioned to benefit from the future recovery in auto production. The rollout of the Company’s OMEGA transformation programme continues, with the ultimate aim of achieving ongoing improvements in efficiency and competitiveness. Recent commercial successes, particularly in hydrogen and electric vehicles (Hyundai, Alstom, etcetera), combined with an innovative technological offering, positions Plastic Omnium as a leading player in clean, smart mobility.

With its solid balance sheet and ambitious strategy to maintain pace with fast-changing mobility needs, the Group is reasserting its intention to be a major consolidator in its market.

Press release