Hydrogen Revolution, powered by OPmobility

Storing energy, reducing emissions and inventing the way forward

At the heart of the automotive industry’s transformation, in a context of stricter environmental standards, OPmobility helps all mobility stakeholders develop innovative solutions.

Leading the way in clean technology, the Group is designing innovative hydrogen solutions for zero-emission electric mobility.

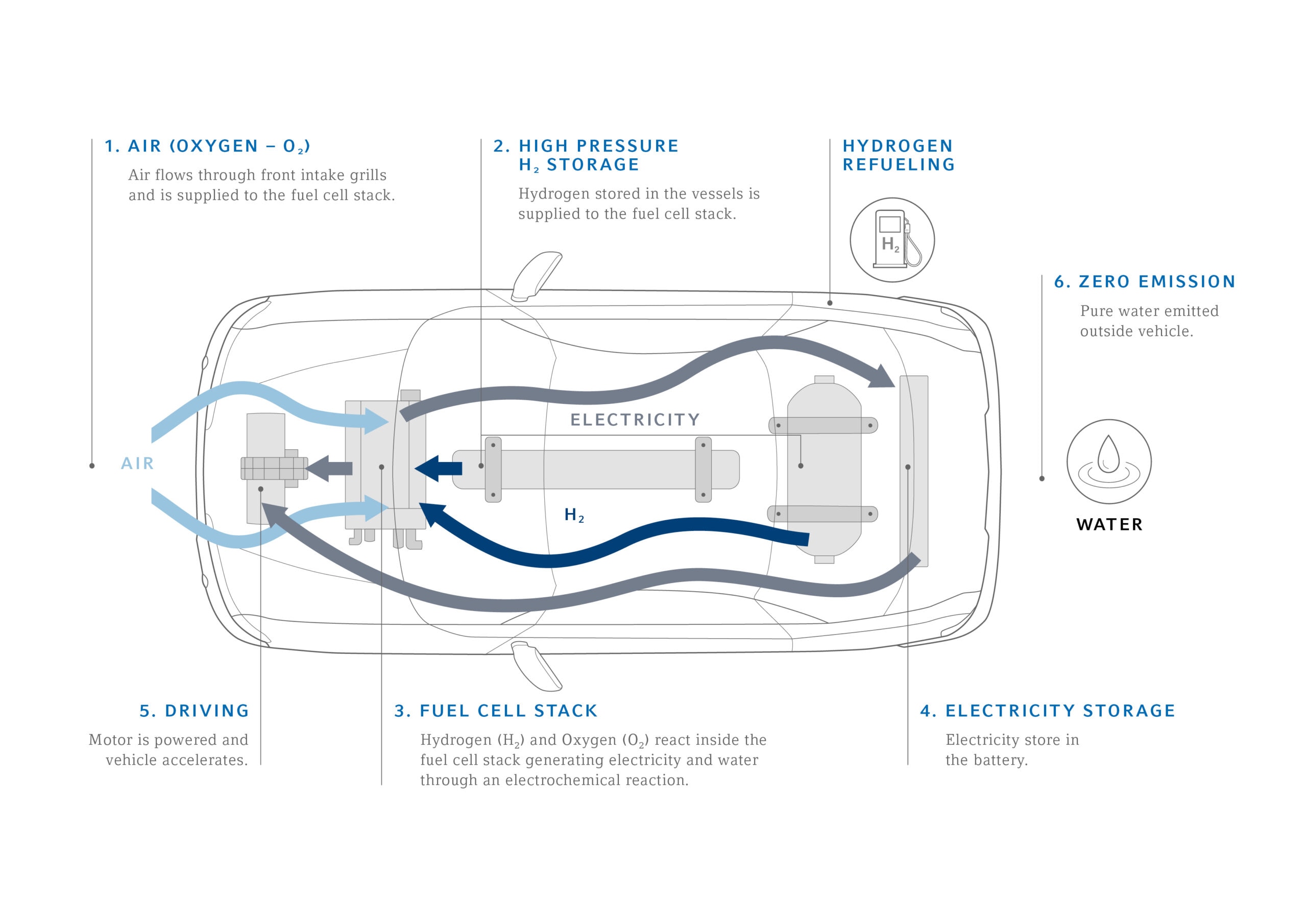

Air, hydrogen and electricity on board: the zero-emission hydrogen car in six key points

OPmobility @ IPCEI Hy2Tech

HIGH-PRESSURE HYDROGEN STORAGE

Our know-how? Designing and producing high-pressure type IV hydrogen vessels, composed of a liner encased in a carbon-fiber shell. Our expertise in filament winding enabled us to obtain European and international certifications in 2019, followed by our first truck contracts.

of hydrogen = 100 km range

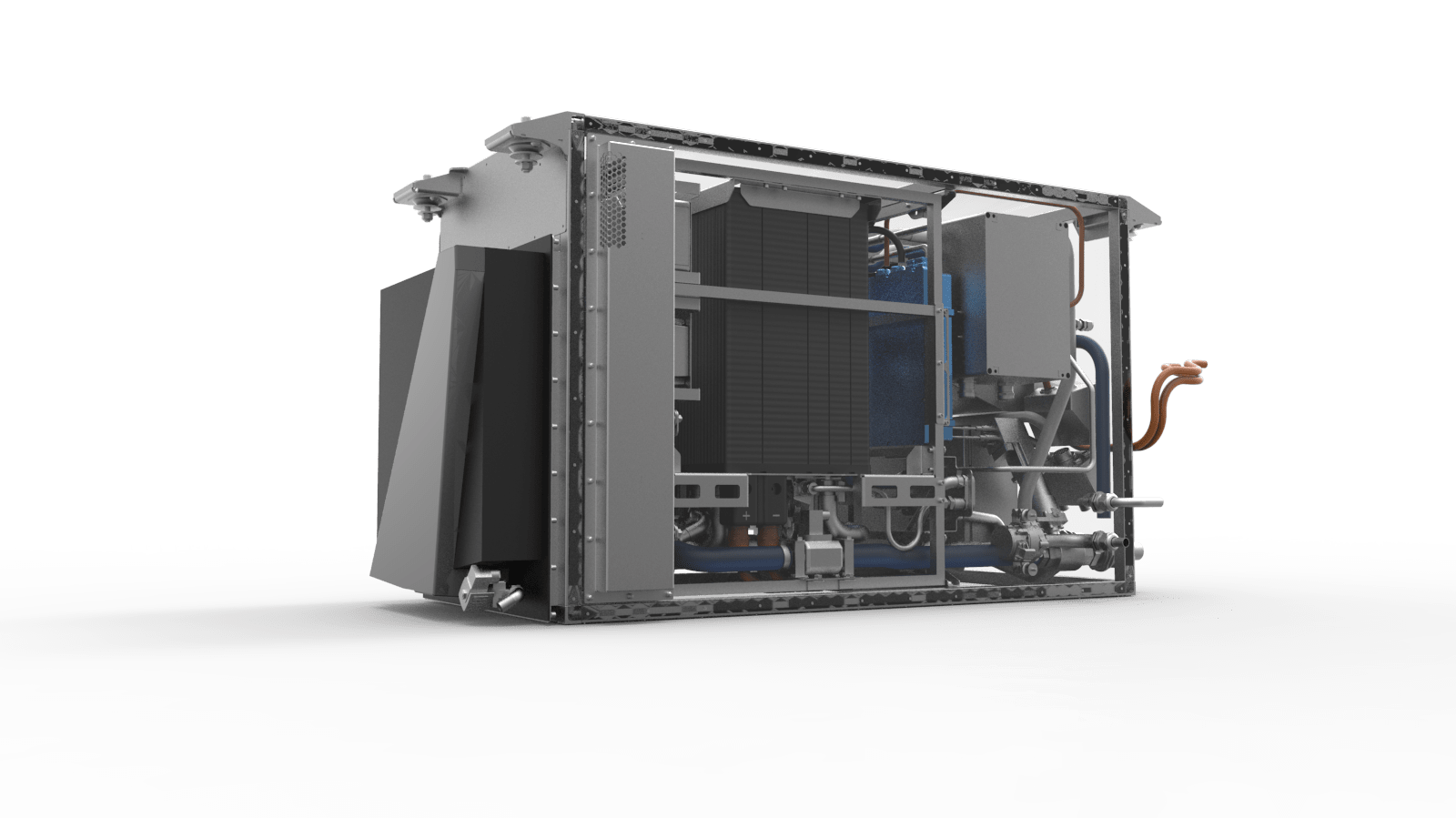

FUEL CELL STACK

The fuel cell makes it possible to generate electricity on board of the vehicle by chemical reaction and to power an electric motor with zero CO2 emissions.

This offers considerable advantages now that clean mobility is both a legal obligation and imperative for our planet.. A sizeable asset, while clean mobility is today a regulatory obligation and an ardent necessity for our planet.

Integrated hydrogen system

The hydrogen system includes the fuel cell stack and “balance of plant” components. A complex system comprising 120 to 150 parts, it manages four complementary integrated functions: Thermal Control, Electronic Flow Management, Compressed Air and Humidifier.

Our manufacturing capabilities